Information from RECYCLING TIMES MEDIA CORPORATION14.06.2019

Western European HCP Market Declines

According to research by International Data

Corporation (IDC), the Western European printer and multifunction (MFP) market

decreased by 5.8% in unit terms in 1Q19 compared with the same period a year

ago. This meant the overall market declined by 286 thousand units and price

pressures led value to also decline by 4.1% to just over .5 billion. There

were few areas of growth and the negative start to the year will continue

throughout 2019.

Inkjet shipments declined 5.4% to just over 3 million

units and both A4 and A3 shipments recorded negative growth figures. Most

declines were from printer devices, but MFP shipments also decreased more than

4%, but not all OEMs saw declines.

Laser shipments declined by 6.1% and as with inkjets

there were few areas of growth. Some markets, such as A4 single-function

printers, declined quite heavily, but there was small growth from A3 single

function printers and A4 monochrome MFP devices. As fewer overall laser units

shipped the value also declined, this time by 2.5%, even though some of the

higher speed segments increased.

High speed inkjet devices also contracted in terms of

units, but the value was up, and the serial impact dot matrix market continued

its decline.

“The decline shown in 1Q19 was in line with

expectations and the markets and this negativity is likely to be reflected

throughout 2019, but there will be some growth from some segments,” said Phil

Sargeant, program director in IDC’s Western European Imaging, Hardware Devices,

and Document Solutions group. “The hardcopy markets are still very valuable to

many OEMs and some traditional markets such as monochrome and inkjet are still

very sizeable even if they are declining.”

Highlights:

· The

overall Western European hardcopy market contracted by 5.8% year on year in

1Q19, recording a shipment figure of 4.6 million units, while the value

declined by 4.1%.

· A4

monochrome MFP showed a small increase of 0.8%, while A4 monochrome printers

declined by 11.2%.

· In

line with expectations, the A3 monochrome markets declined by double-digit

figures.

· Most

color laser segments saw surprise declines but there was solid growth from the

niche A2 printer market.

More information please visit: www.idc.com

Details:https://www.rtmworld.com/news/western-european-hcp-marke-continue-to-contract/

14.06.2019

Worldwide HCP Market Declines

According to IDC report, Worldwide shipments of hardcopy peripherals

(HCP) decreased 3.9% year over year to 22.8 million units in the first quarter

of 2019 (1Q19).

The brightest spot for the quarter was the

year-over-year expansion of color inkjet multifunction printers (MFPs) in the

11-20 ppm range, which grew 4.7% to more than 6.2 million units shipped.

Notable highlights from the first quarter include:

· Ink

Tank devices continued their positive momentum recording a 23.4% year-over-year

gain in unit shipments in 1Q19. Asia/Pacific (excluding Japan) and Latin America were the top two regions for ink tank shipments with 1.7 and 1.0 million units

shipped in the quarter, respectively.

· Inkjet

shipments decreased 2.1% year over year to nearly 13.7 million units shipped.

Asia/Pacific (excluding Japan)

was the top region for inkjet shipments, growing 8.8% year over year to more

than 3.5 million units in 1Q19. Western Europe, the second largest market,

contracted 5.4% while the United

States, the third largest market, declined

4.8% year over year.

· A3

color laser MFPs continued on a positive trajectory with a year-over-year gain

of 1.0% to nearly 600,000 units shipped.

· HP

Inc. declined 3.5% year over year with global shipments dropping to less

than 9.4 million units. However, two of HP’s top 3 regions, Western Europe and

the U.S.,

exhibited year-over-year gains of 2.8% and 2.6%, respectively.

· Epson regained

the top inkjet position from Canon in Asia/Pacific (excluding Japan) albeit

at a marginal share advantage of 0.7%. Epson grew by about 210,000 units year

over year due to the improved sales of its new generation of more compact ink

tank printers, which were largely responsible for the growth of the ASEAN

market and the biggest winner in China as the only one with a market

share gain this quarter.

Details: https://www.rtmworld.com/news/worldwide-hcp-market-declines/

|

Worldwide Hardcopy Peripherals Market, Unit

Shipments, Company Share, and Year-Over-Year Growth, Q1 2018 (based on unit

shipments) |

|

Companies |

1Q19 Unit Shipments |

1Q19 Market Share |

1Q18 Unit Shipments |

1Q18 Market Share |

1Q19/1Q18 Growth |

|

1. HP Inc. |

9,369,660 |

41% |

9,704,972 |

41% |

-3.5% |

|

2. Canon

Group |

4,349,818 |

19% |

4,393,457 |

18% |

-1.0% |

|

3. Epson |

4,317,575 |

19% |

4,443,484 |

19% |

-2.8% |

|

4. Brother |

1,670,633 |

7% |

1,783,246 |

8% |

-6.3% |

|

5. Kyocera

Group |

533,153 |

2% |

547,539 |

2% |

-2.6% |

|

Others |

2,596,669 |

11% |

2,896,050 |

12% |

-10.3% |

|

Total |

22,837,508 |

100% |

23,768,748 |

100% |

-3.9% |

|

Source: IDC Worldwide Quarterly Hardcopy

Peripherals Tracker, May 2019 |

14.06.2019

New Compact Printers from Epson

Epson America has expanded the WorkForce®

and Expression® line of printing solutions, including one WorkForce home office

model and two Expression printers designed for today’s busy families. Epson’s

latest affordable, compact printers – the WorkForce WF-2830 All-in-One Printer

and Expression Home XP-4100 and Expression Premium XP-6100 Small-in-One®

Printers.

The new WorkForce and

Expression models are compatible with Alexa, Siri and Google Assistant for easy

hands-free voice-activated printing on command1. The models also support

driverless printing from Chromebooks; users can print right from their desktop

without installing or maintaining printer drivers for the WF-2830, XP-4100 and

XP-6100.

Packed with convenient

features, fast print speeds and easy wireless connectivity for printing from

tablets and smartphones2, Epson’s new All-in-One and Small-in-One printers

offer an affordable solution to enhance the at-home printing experience.

Home Office Solution: An efficient,

reliable printer, the WorkForce WF-2830 offers fast print speeds plus wireless

connectivity to deliver professional-quality documents, reports and proposals.

This compact all-in-one features a convenient 30-page Auto Document Feeder,

auto 2-sided printing, and print speeds of 10.3 ISO ppm (black) and 4.5 ISO ppm

(color) to enhance productivity. The WF-2830 leverages affordable individual

ink cartridges, including pigment Black Claria® ink for crisp black text in

professional documents.

Efficient Everyday

Printing: A compact, convenient printer, the Expression Home XP-4100 provides

quality prints for on-the-go college students and families. Printing, copying

and scanning is right at the user’s fingertips with the 2.4” color LCD. This

sleek printer features instant-dry ink for truly touchable photos and

documents, and increases productivity with a 100-sheet-capacity paper tray plus

auto 2-sided printing. Compatible with the Epson Creative Print App, students

and families can easily create custom projects such as photo collages, greeting

cards, stationery and more, right from their iOS or Android devices.

Impressive Photo Quality:

A versatile, fast printer, the Expression Premium XP-6100 delivers superior

photo and document quality for today’s fast-moving families. With affordable,

individual 5-color Claria Premium Inks, the XP-6100 outputs stunning borderless

photos up to 8” x 10”, plus sharp text. Whether running a creative household or

starting your own company, the XP-6100 touts an array of convenient features

such as print speeds up to 15.8 ISO ppm (black) and 11.3 ISO ppm (color) †, 4”

x 6” photos in as fast as 15 seconds3 and auto 2-sided printing. Built-in USB

and memory card slots4, an improved 2.4” color LCD and dedicated photo and

CD/DVD trays offer additional convenience.

Details:https://www.rtmworld.com/news/new-compact-printers-from-epson/

14.06.2019

World’s First Smart Tank Laser

Printer

HP

has announced the launched of new toner tank printer series Laser NS 1020 and

Laser NS MFP 1005. The company claimed the HP Neverstop Laser is designed for

small business owners in emerging markets and a reimagined HP Smart Tank for

home.

Key features include:

· Up to 5,000 pages without

interruptions

· Print up to 5,000 pages right out of the box with virtually no interruptions-perfect

for high-volume printing

· Reload mess-free toner in seconds

· A revolutionary supply system lets you quickly and easily reload toner

levels in 15-seconds without making a mess

· Original HP quality and unbelievable savings

· Get original HP quality printing for a cost per page competitive with

imitation cartridges, with up to 80 percent cost savings on HP original toner

· Connected and mobile

· Easy mobile scanning and printing with best-in-class mobile print app,

HP Smart App

HP

Neverstop Laser will first launch in China;India and selected countries

in SEA, summer 2019; Russia and selected countries in CEMA, July 2019; LAR, August 2019.

The

new HP Smart Tank will first launch in June in all emerging market countries in

Asia Pacific except India,

which will ship in July. Also shipping in July are the APJ developed markets,

EMEA emerging markets, and LAR countries.

Smart

Tank is now available on HP’s Chinaonline shop. The prices are:

Laser

NS 1020: RMB¥1599

Laser

NS 1020w: RMB¥1649

Laser

NS MFP 1005: RMB¥1899

Laser

NS MFP 1005w: RMB¥1949

The

refilled toner set is RMB¥199, with two toner tanks of estimated yield of 5,000

pages.

Details:https://www.rtmworld.com/news/worlds-first-smart-tank-laser-printer/

14.06.2019

Examining the Quality

of Toners

There have been recent

reports about the bad quality and health consequences of Chinese produced

toner. Where does bad quality come from?

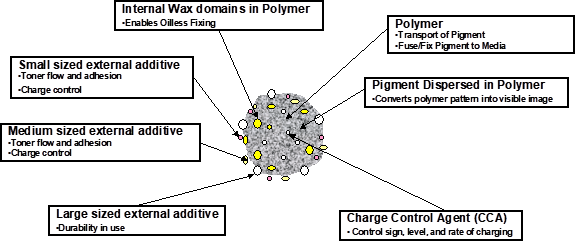

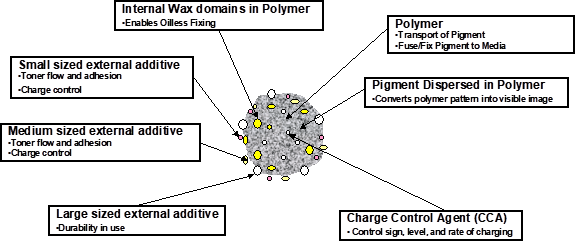

Just as with any product

from any country, the quality of toner depends on the manufacturer of that

product and the decisions that are made by the formulator, and the purchasing

and manufacturing departments. The composition of any powder toner consists of

pigment, polymer, wax, charge control agent, bulk additives and surface

additives.

In general, lower-cost

raw materials, wherever they are sourced, are likely to contain “impurities”

that could possibly be undesirable from a health and safety perspective. A

variety of such trace materials have been identified as potential health

hazards in toner. One category of the materials of concern includes

Volatile Organic Compounds (VOC) – including Styrene, Benzene, ethylene glycol,

formaldehyde, methylene chloride, tetrachloroethylene, toluene, xylene, and

1,3-butadiene.

Such materials, if

present in toner, can be released into working the environment during the

fusing/fixing stage of the print process. As the toner that is transferred from

the photoconductor to the paper or other substrate is heated reaching 130 to

180°C any VOC content of the toner is volatilized and exhausted from the print

engine by the machine cooling system through the fan and duct to the space in

which it is being operated.

Other sources of

environmental pollutants from toner are toner dust and loose toner surface

additives. All toners comprise finely divided particles that have a mean

particle size of anywhere from five to ten microns. This mean is only the

middle point of the toner particle size range, and toner can contain particles

of size well below five microns and well above ten microns

The removal of particles

from any source of dust that penetrates into the gas exchange region of the

lungs depends on a variety of factors but significantly depends on the diameter

of the particle. Hazardous particulate size is primarily less than five

microns, and particle sizes of 2.5 microns (PM2.5) are often used in the U.S. to

describe non-respirable dust. The particle size distribution (PSD) – the range

and percentage content of toner particles by the size of any toner – depends on

the toner composition and the toner production conditions. With respect to

toner dust less careful, and typically lower-cost manufacturing can be responsible

for toners that “dust”. Such toners might have a mean particle size that

matches that required for operation in a particular engine. but have a psd that

is too broad or has a high fractional content of ultra-small-sized toner

particles.

In addition, the surface

additives that are used to promote toner powder flow, durability and charging

need to be processed in the production of the toner such that they are

sufficiently well attached to the toner particle surface to prevent their

release from the surface of the toner particles during the entire printing

process.

This process is highly

agitating: starting with the agitative processes in the print engine of

delivery from the toner reservoir, application to the developer roller,

transfer to the paper or substrate and on to the downstream processes of

printing. The typical surface additives used in toner are ultra-small in size

compared to the toner, with sizes ranging from eight to 250 nanometers, well

below the PM2.5 particle size considered to be dangerous from a respirability

perspective. Typical materials used include silicon dioxide, aluminium oxide

and titanium dioxide.

In addition to the dust respirability factor,

there has been recent attention to the question about the foregoing gives some

idea of the range of issues regarding the development and manufacturing of

toner, and these matters concern all toner manufacturers worldwide. That the

manufacturing of toner, particularly for the aftermarket, has shifted

geographically from Europe and North America to Asia brings the focus to that region. Production in China is, of course, an important

development of this trend. The other aspect of this shift is that there has

been the development of raw material supply in Asiain support. Sources of locally manufactured toner ingredients have been

established and developed. Some of those companies are new to the toner

manufacturing industry and have been on a “learning curve” regarding the

requirements for materials for toner

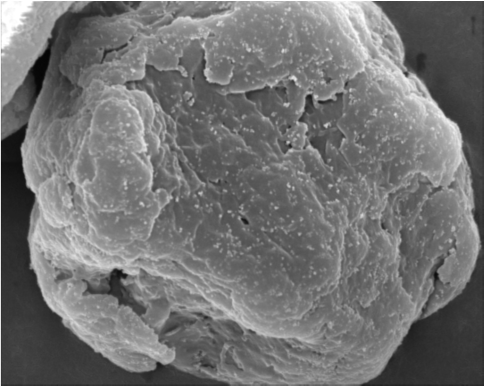

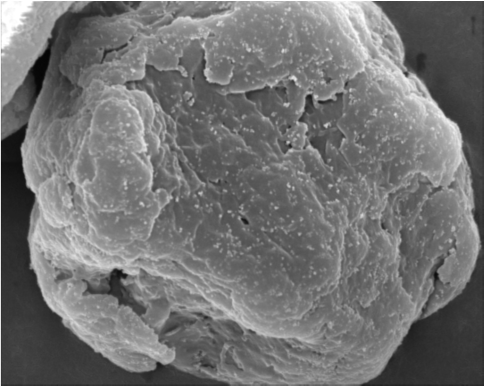

the effect on the health

of ingestion of titanium dioxide. The scanning electron microscope (SEM)

picture below shows surface additives as very small white dots on the toner

particle.

With this geographical

shift, new manufacturing capacity, as well as transferred production capacity,

has been established. Simultaneously, there has been a constraint on production

caused by softening of demand, particularly for types of toner most popular in

the aftermarket. This imbalance in the “push-pull” between the available

capacity and market demand has generated severe price competition and depressed

profitability in the toner manufacturing industry, particularly in the more

recently developed toner manufacturing in Asia.

The natural response by

toner manufacturers in attempts to mitigate this is to economize and attempt to

reduce unit cost by reducing raw material and manufacturing costs. For some

manufacturers, this means that they are using lower quality polymer, pigment,

magnetite, wax, and other ingredients and increasing production throughput

rates with consequential degradation of PSD and integrity of the toner and its

additives.

In general, but not

universally, lower cost raw materials, and the use of raw materials, that are

not designed for toner use, results in issues of high VOC content and content

of undesirable trace materials. The changes made in raw material compounding

conditions to increase throughput rate resulting in higher heat and energy

input can cause degradation of raw materials and the creation of VOC fractions.

Higher production

throughput rates in fine grinding to reduce energy cost content per kilo and

changes to classification to maximize product yield, both strategies to reduce

product cost potentially increase the likelihood of “dusting” of toner in use.

There is no such thing as

“Chinese Toner” as a homogenous set of products. As has always been the case in

the toner industry, irrespective of the location of manufacture, there are

within toner manufacturers professionally oriented, responsible manufacturers,

which develop and manufacture their products responsibly with the objective of

maintaining standards of performance and minimization of any environmental or

health impact.

There are also those companies

that do not follow the same policies. It is important in any purchasing

decision, whether as a reseller or user, that the full cost of purchase rather

than the price is considered, as poor quality can significantly impact the

cost. The efficacy of Chinese toners just like toner from any other

geographical regions vary. Not all are bad or good. Buyers should be

conscientious in their evaluation of products before they purchase.

Details:https://www.rtmworld.com/features/examining-the-quality-of-toners/

14.06.2019

Dealing

with China:

two leaders respond

Vincent Chen says building trust is the key—he is president of the HK HaoYinBao Group, known better as HYB

Toner

Do you see China taking on a more or less of a

significant role in the imaging supplies industry in the future? Why?

Yes. The

Chinese products and their manufacturers are definitely getting more and more

important to the imaging supplies aftermarket. There are many different

reasons, but in my opinion, some Chinese manufacturers have improved their

engineering development and strength. At the same time, of course, we also

notice that those who fail to deliver quality products are fading away.

What questions are you asked the most from

foreign companies wanting to deal with you as a Chinese company?

Most of our

customers don’t treat us any differently from other international suppliers.

It’s true that some have had bad experiences with some Chinese suppliers and

became more cautious. From the questions we are asked I can tell you that the

worst experience they suffer from is the stability of the products.

What advice would you give to an

international company wanting to deal with any Chinese company?

There are

always good and bad business people in every nationality and our customers have

suffered serious problems with their suppliers in other countries too. So, we

shouldn’t “label” companies simply by their nationality. As long as the

manufacturers or suppliers are working with a principle that is in line with

your standards, then you can get a deeper approach to understand these

companies, business styles and how they manage their quality control.

Gradually, you can decide if these companies are trustworthy or not.

How important is it for foreigners,

wanting to do business with China,

to actually visit China?

From the

outset, all buyers should have done some research and had a conversation with

the experienced representative of the suppliers. In my experience, our smartest

customers have their own “FAQs” which help them to identify if a supplier is

worthy or not. E-commerce, however, has seen many businessmen become lazier in

communicating with their suppliers. They are doing less due diligence to

discover if suppliers are suitable or not. I think this is the reason why

problems are occurring more. It’s like the marriage between a boy and a girl

who only know each other for a week. You can imagine how risky the marriage

will be.

Providing consistent quality and non-infringing

products are important for your company, yet not all Chinese companies hold the

same values. Why?

Many company

owners didn’t realise the industry potential when they started out in business.

They only wanted a piece of market share and were surprised at how quickly this

industry developed.

While our

initial purpose at HYB was not to build a company that would sit on top of the

industry pyramid, I found our people are not the kind that likes to lose the

trust of our customers. The relationships we have with our customers are

mutually beneficial with many customers helping us to further develop our

products. With such a huge responsibility, you always try to find every means

possible to invest in and improve your quality systems to ensure the consistency

of your products. Customers are very demanding in their expectations for

“trouble free” products. This thinking is reasonable so we will never stop the

development of patents and systems to meet the needs of our customers.

Ding Li

invites you on a field trip—he is Chief Technology Officer (CTO)

at Apex Microelectronics Co.,Ltd

Do you see China taking on a more or less of a

significant role in the imaging supplies industry in the future? Why?

China must take on a more significant role in the imaging supplies industry in the

future. Its huge population and booming economy have caused China to have a

more a significant role on the world stage. In keeping with this trend, both

for homes as well as business there is a growing demand for the imaging

industry too. Chinese enterprise has the advantage of resources and commerce

from its huge domestic market. This is all true for Apex which has developed,

mass produced and released controller chips for multifunctional laser printers

in 2018. Another kind of controller chip is in its validation phase. We expect

to continue being more active in meeting both domestic and international

demands required by the imaging industry.

What questions are you asked the most from

foreign companies wanting to deal with you as a Chinese company?

The speed of releasing new products, patents, and product quality is the

biggest issue among our customers. In response, I would like to say Apex has

accumulated a significant 18 years of deep understanding about chip technology.

Our highly-educated, experienced chip design engineers are able to accelerate

the speed to release the new products. At the same time, our well-qualified and

experienced IP engineers focus upon patent analysis, risk avoidance, and

patented product design. We verify the chips in our Provincial Printer SoC Chips Engineering Center and Provincial Research Center using

newly equipped test and analysis devices, valued at .5 million in 2018. By

providing a strong quality system we can address any concerns customers might

have.

What advice would you give to an

international company wanting to deal with any Chinese company?

Have a field

trip. I welcome any foreign friend to visit and explore the full process of chips

development and the breakthroughs we made in technology innovation. Visitors

tell us their on-site visits to Apex opens their eyes to the level of

commitment in terms of research, development, manufacturing and quality

control. I believe such a real, face-to-face communication will make us strong

partners.

How important is it for foreigners,

wanting to do business with China,

to actually visit China?

There is an

old Chinese saying, “To see one time is better than to hear a hundred times”.

For foreigners who want to do business with China, it is not enough to simply

contact a company online. There is only one way to experience Chinese culture

and advances in technology. You must visit and travel on China’s high-speed

trains, climb the Great Wall and visit Apex’s experimental and testing centers,

and automated production lines. I urge visitors to use Apex’s 3D X-ray analysis

equipment to take a stereogram of chips… I believe the impression formed by

foreign friends will have a deep impact upon them and they will be encouraged

to do business with Chinese companies.

Providing consistent quality and

non-infringing products are important for your company, yet not all Chinese

companies hold the same values. Why?

Most Chinese

companies hold such values about providing consistent quality and

non-infringing products. Having values is easy, however, but it is hard to

realize. We have gained our current market position because we have focused on

intellectual property rights and technical competence. This includes encryption

analysis, chip design, product testing and patent analysis technologies. This

is why Apex can design non-infringing patented products with high quality and

firmware resistance. Those Chinese companies that cannot realize the above

values are limited in technology or patent knowledge. As an industry leader,

Apex is willing to work with more Chinese companies to achieve common

development and to provide clients with design consistent quality and

non-infringing products.

Details: https://www.rtmworld.com/features/dealing-with-china-two-leaders-respond/

14.06.2019

China’s Long

History of Innovation Leadership

China only joined the World Intellectual Property Organization (WIPO) in 1985. Some,

when learning of this, are surprised and that’s because in the West can trace

back the origins of patents at least 2,500 years ago to the City of Sybaris,

originally part of Ancient Greece and now part of southern Italy.

The elders of

the city granted protection rights to anyone who “invented” something of a

luxury. Usually recipes for meals or refreshments. The inventor would get

exclusivity for a year and therefore have a short-term monopoly to exploit, but

the inventor had to lay open the exact process, ingredients and steps for all to

see.

The

question is why did it take Chinaso long to join the WIPO? Was it that they were not inventors or was it more to

do with the open culture and the way in which totalitarian rule decided how the

civilization should be controlled?

Throughout

history, the Chinese have been recognized as prolific inventors: gun powder,

the compass, paper, print and so on. So, this is not the reason. The fact is

that the through the ages the ruling dynasties didn’t believe that useful

inventions should be monopolized for the financial benefit of a few when the

masses could benefit from the new modern technology.

Cai Lun is

said to have invented paper in China more about 1,914 years ago. He decided to use plant fibers in his process

resulting in a thinner, whiter parchment that when dried and cut created a

perfect substrate for painting, printing, drawing, writing, flying (kites) and

a host of other uses. He took his invention to the emperor, who decreed that

every village should be taught how to make it so that the greater population

could benefit. No patent, no exclusive period for exploitation, just a decision

to allow the people to benefit. Lai received perhaps the greatest reward of all

in being known as the inventor of paper for eternity.

As with most

inventions, there is no such thing as an original thought. Someone somewhere

has had the same thought, taken past technologies and inventions and made them

better, faster or cheaper. Lai was certainly aware of papyrus parchment used by

the Egyptians 2,000 years before. He improved it, used what was local and made

history. Today a sheet of paper goes a long way, has thousands of uses and

costs about half a cent. You will find it in every corner of the world and it

goes down as one of man’s most successful inventions. A bit like the wheel or

fire.

Had paper

been invented in modern times in the West, no doubt it would have been patented

and exploited and far less successful. It is not a stretch to envision a

paperless world many decades ago since the need to have a substrate to draw or

write, upon is universal. Paper’s success as an intrinsic part of global life

for almost 2,000 years prevents the newer patented technologies which are

already here, from creating the paperless world. The entry cost is simply too

high compared with half a cent, and of course, you need a source of power. No

batteries needed to read a sheet of paper. By the way, did I mention you can

use both sides, recycle it, screw it up and throw it in the wastepaper basket

only to be able to retrieve it, flatten it out, and use it again? What an

invention! We won’t see a paperless society any time soon.

China was a late starter to patents. The U.S. led the world in patent

filings, double that of European countries for many, many decades. Now the

table has turned. The Chinese file more patents than any other country. Three

times as many as the U.S. who are now in second place. Now China wants to protect its own

technologies as it morphs from a replicator of products invented elsewhere to a

technology-driven economy leading the world into the future. The sleeping giant

has awakened. In 1979, Deng Xiaoping declared an open policy for China. “To be

rich is beautiful,” he declared. The West was quick to exploit the cheap labor

and moved production from Taiwanand Hong Kong to lower-labor-cost Chinese

factories. Chinese government-supported, state-owned enterprises, giving land

and money for building factories filled with German-made machines.

Thousands

upon thousands of companies began producing whatever the Western consumer

needed. A typical worker would work six days a week at ten-hour shifts, sleep

in dormitories holding up to 16 people to a room for about 0 a month in pay.

Today it is a little different. Dorms give way to high-rise apartment blocks

for workers, salaries have quintupled, the pedal bikes have given way to motor

cars to a point where there are so many cars, it is quicker to use a pedal

bike. Infrastructure investments over the years have built good highways, fast

“bullet” trains up and down the country, the world’s longest bridge from Hong

Kong to mainland China,

and space landings on the dark side of the moon. The small towns have become

new cities, the skyscrapers fill the horizon and the pace of change is

phenomenal. What’s next?

China achieved in a decade what it took the British 150 years to accomplish in the

industrial revolution in order to bring people out of abject poverty. It hasn’t

happened by chance. Every step has been carefully planned and thought through. China has a

50-year plan, it has patience, it is determined and it sits on three trillion

in U.S. dollars. It has invested much back into the US, prompting Warren Buffet to say,

“Whether we like it or not, we all work for the Chinese.” The Chinese consumer

market is now growing fast, they have plenty of money and there is nothing they

won’t buy. They now have more millionaires than the U.S.and Prada, Channel, Dior, Louis Vuitton, Rolls Royce and Bentley are all

selling more in China than any other marketplace. Chinese workers now get more paid time off than a

typical US worker. GDP value in Chinais now nearly 20 percent of the world economy, and sets China on a course to be world’s biggest economy

soon, taking the top spot from the U.S. When this happens, it will

signal the first time that a “developing country” nudges a leading “developed

country” to the sidelines. China will want its say on the world stage, the West will not be happy about it. The

world is being all shook up, as Elvis used to sing.

I

figured out a long time ago that you can’t compete with China, so run

toward it and see what it can do for you.

The Chinese

ideology of building “cluster” cities to dominate world markets in one

government supported area is something not replicated in the West, but it has

huge benefits and impact. Sock City, located in Datang, Zhejiang Province, dominates the world sock markets producing 19 billion pairs a year,

Shenzhen dominates the world electronics’ markets and Zhuhai dominates the

world’s cartridge consumable markets with more than 600 companies located in

and around the city. Zhuhai is not going away. It is impacting the global

marketplace. It produces a range of qualities, very poor, poor, not so bad, ok,

pretty good, very good, outstanding and excellent. Some world class companies produce

the best, patent-safe compatibles that fully comply with E.U. and U.S.regulations at prices far below a remanufactured cartridge price. These

world-class companies will continue to grow while patent infringers will get

sued and forced out and poor quality companies disappear as they lose

customers.

China is a dominant force in our industry. There is the worst and the best there.

There is as much fear for them doing business with the West as the West is

fearful of doing business with them. But it is the place

to do business if you want to survive and prosper in the year of the pig.

Details:https://www.rtmworld.com/features/chinas-long-history-of-innovation-leadership/

14.06.2019

Right or wrong, headlines questioning

Chinese product quality are likely to continue

There is no

underlying reason why products manufactured in China should be of lesser

quality than similar products manufactured in more mature economies

elsewhere in the world.

Chinese

technology has advanced rapidly over the last few decades, an advance no more

vividly demonstrated by way of a Chinese launched, and Chinese operated,

robotic lander on the far side of the moon, currently conducting research that

may one day help lead to the development of a permanently manned lunar base.

To possess

the cutting-edge technology necessary to place a robot on the

moon should conclusively disprove the notion that Chinese products are

inherently inferior. Of course, this is just one example but, for anyone who

has seen and experienced Chinese infrastructure in terms of architecture,

transportation, manufacturing facilities, and scale, etc., they also should

know there is no underlying reason why any of the products made in China should

be inferior.

200

million iPhones are made in China every year. How many other globally recognized, high-tech, mass-market devices

are produced with such consistently high-quality anywhere else in the

world? Except, perhaps, for ink and laser cartridges already manufactured in China by

various OEMs!

So, why is

it, in our less than glamorous world of ink and toner, that we constantly

experience new headlines for poor-quality aftermarket cartridges coming

out of China?

Whether it is for claims of poor print performance, infringement of third-party

intellectual property, toxic materials in plastics, carcinogens in the toner

powder, etc., the list of headlined deficiencies seems never-ending.

The reasons

for this are two-fold.

First,

because some of the products are undoubtedly poor-quality and regardless of how

isolated these occurrences may be, they represent a short coming that justifies

some of the headlines and, second, because Chinese new-build cartridges (NBC’s)

are a disruptive threat toward the old order.

Let’s deal

with these two sets of circumstances separately.

We all know

that prices (for example in the Amazon marketplace) for new-build cartridges

are often at, or below, what we would expect the bill of material (BOM) cost to

be. This means two things. Firstly, manufacturers are skimping on the materials

to reduce the cost and, secondly, poor-quality (inconsistent) products, that

didn’t meet their original customers’ requirements are being liquidated, at or

below cost, rather than being re-worked or destroyed.

We all know,

at least for the three or four Chinese top-tier manufacturers (with a combined

market capitalization in excess of US billion), there’s no excuse for an

inferior design that results in poor-quality performance, and there’s no excuse

for ignoring the build requirements necessary to consistently meet a

specified performance standard.

There

is no reason why a Chinese new-build cartridge from a top-tier manufacturer

should not consistently match the performance of an original brand cartridge.

Few should

doubt the ability of a top-tier Chinese manufacturer to develop a specification

for manufacturing a product that is at least the equivalent, in terms of

performance, to that of the original brand product it’s designed to replace.

However, more may doubt the commitment, or current ability, of a top-tier

manufacturer to utilize technology to ensure it consistently meets that

manufacturing specification.

Technology

may, for example, involve the use of robotics designed to eliminate human error

in the manufacturing process but, perhaps more importantly, it may also

require the use of information technology to help manage (for example) the raw

material supply chain. If the right materials are not in the right place at the

right time, how often may an agreed bill of materials have been sacrificed to

meet a customer committed delivery date rather than delaying production until

the specified components become available?

Whichever way

you look at it, it’s no good spending

money implementing world-class Enterprise Resource Planning

(ERP) software, and then limiting its use to store data that is

later downloaded into Excel spreadsheets for mission-critical operating

decisions. This approach doesn’t work, it sidesteps the controls and

efficiencies that effective use of software brings and can often be

a shortcoming responsible for inconsistent product quality.

If

the Chinese manufacturers wish to remove themselves as targets for headlines

denouncing the performance of their products, then they

must implement the processes and discipline necessary to achieve

consistent quality performance.

Until enough controls

and processes are in place to prevent these issues, those who stand to lose the

most from the threat of disruption will continue to do

everything possible to exploit the weaknesses. This will be

accomplished, at least in part, by sponsoring headlines designed to cast doubt

on the capabilities of the potential disruptors. It’s no different from the

Tesla detractors headlining a negative story about an auto-pilot incident, the

Airbnb detractors headlining a client who trashed a room, or the Uber

detractors headlining a rogue driver incident. Those who stand to lose the most

will invest some of their profits to highlight incidents that harm the

reputations of the disruptors because this is where the greatest threat to

their future profit comes from.

However, it’s

not just the negative headlines centered around product quality that serve to

limit market penetration of Chinese built alternative cartridges. There’s a

legacy distribution system in place that protects the existing manufacturers,

the wholesalers, the distributors, and the buying groups, and that serves to

protect the old order to the detriment of the resellers and their customers.

Until alternative technology is available to the resellers that allow them and

their customers to “pull” the products they prefer instead of being “pushed”

the ones their suppliers are currently motivated to provide, Chinese

alternatives, regardless of their quality, are likely to continue to experience

limited success.

If technology

solutions become available which are subsequently embraced by the resellers,

the barriers that have helped preserve the legacy players’ market share

are more likely to be broken down. However, even if these technology

developments do occur, it will be to no avail unless the Chinese-manufactured

alternatives that could, in these circumstances, finally be facilitated into

the distribution network are not 99.9 percent reliable, 99.9 percent

of the time.

Details:https://www.rtmworld.com/features/right-or-wrong-headlines-questioning-chinese-product-quality-are-likely-to-continue/

14.06.2019

European Trade Association is

Growing its Marketplace through the EU’s Green Initiatives

The European

Toner and Inkjet Remanufacturers’ Association (ETIRA), has represented the

interests of remanufacturers of (Original Equipment Manufacturers) OEM

cartridges and related service providers across the European Union (EU) since

2003. We work on topics like quality/standardization, legal and regulatory

advice, public relations, member contact platforms and more. Our code of

conduct, depicted by the ticked-R collective mark, gives our members a

competitive advantage in the industry.

To enhance

our outreach, ETIRA is also active in the CER, the Brussels-based European

remanufacturing council. ETIRA now has 40 members.

2018 was

another busy year for the European Toner and Inkjet Remanufacturers

Association (ETIRA). In summer, we thanked outgoing President Christian

Wernhart for 12 years at the helm of our association. Industry veteran David

Connett is now leading ETIRA on its path to growth.

Last year,

the EU made the circular economy a key policy initiative. This was music to our

ears, as cartridge remanufacturing is textbook circular economics. A February

2018 EU Commission report on cartridge reuse, which we had asked for, clearly

called for more EU action to promote remanufactured cartridges.

If you reuse

your cartridge as a cartridge for as many cycles as possible and thereafter

recycle its materials, you have the lowest environmental footprint possible.

Building on that study, ETIRA is now actively lobbying the EU to facilitate the

reuse of cartridges. We call for an EU ecolabel for remanufactured cartridges,

and for public procurement programmes to give preference to remanufactured

products.

We also

called for an end to OEM anti-remanufacturing practices such as the empoyment

of smart chips, unfriendly cartridge designs, patents on cartridge reuse,

market lockout sales structures, refusals to honor printer warranties and more.

For too long,

the OEMs have refused to further “green” the printing process. The only thing

they did was to reduce printer energy use, but we argued that doing so has

delivered little environmental benefit. If we really want to “clean up”

printing, you need to reuse the paper and the cartridges!

We also

insisted that the EU acts against the patent-infringing, non-OEM new-build

cartridges, or “clones” as we call them. These products from Asia have achieved a large market share, mainly because they are very cheap.

But this fast growth came with a cost: the quality of many products is

not so good. Also, many do not respect OEM patents, so if you buy them you too

can be sued by the OEM. ETIRA published a free “Guide to Clones,” which

educates our members on the risks they run when buying non-OEM new-built

cartridges.

Recently, we

identified another worri some issue with the clones. In late 2018, ETIRA and

others had a German laboratory test eight to nine clones purchased off the

internet, and it turned out that most of them contained levels of the flame

retardant DecaBDE above the allowed EU limit. DecaBDE has been banned in

the EU for many years, and may be used in materials of products like

electronics but up to only .1 percent. It was shocking to see that some

contained levels up to 14 to 17 times the allowed limit!

This problem

occurred not only under the small suppliers, but also the well-known large

Asian names apparently use too much of a chemical that is basically prohibited

in the EU for health and safety reasons!

This is why

we are telling the EU that now is the time for them to act. We are being

squeezed between the OEMs and the clones, as a result the European cartridge

remanufacturing industry is able to remanufacture only 10 to 20 percent of all

OEM cartridges put on the market. Yet, if all the aforementioned market

barriers were removed, that number could be 75 to 90 percent!

So at a time

when the EU wants more products to be reused, and citizens and companies are

trying to lower their carbon dioxide footprint and reduce their use of natural

resources, a remanufactured OEM cartridge should be the first choice of all

business and personal cartridge users in the European Union.

Under the 2018 circular economy initiative, the ETIRA message is coming

across. We are seeing growing interest in our work from authorities at the EU

and the national level. Our work will result in more opportunities for

cartridge remanufacturing, and a cleaner Europe.

Follow us on Facebook and Linkedin to stay tuned! For more information,

visit www.etira.org.

Details:https://www.rtmworld.com/features/european-trade-association-is-growing-its-marketplace-through-the-eus-green-initiatives/

14.06.2019

INDEPENDENT

TESTS REVEAL: NEW-BUILD CARTRIDGES COMPARE FAVORABLY WITH OEM

Following

extensive, confidential testing by Buyers Lab (BLI) on two very popular laser

printer cartridge series, LD Products is boasting it’s Chinese-made, new-built

cartridges (NBCs) will be a winner with US dealers looking for high-yield,

non-infringing, quality cartridges targeted for use in MPS environments.

In

order to complete the testing objectively and from a true end user perspective,

BLI confidentially sourced NBC print cartridges from dealers during the first

quarter of 2019 and compared them with the genuine OEM cartridges. According to

BLI, the evaluation process took one month, with devices running at accelerated

volumes and using an industry standard target, to accurately compare the

cartridges on print quality, yield and overall value.

“Dealers

know and trust BLI’s extensive testing methodology and, to our knowledge, this

is the first time any new-build or extended yield cartridges have successfully

completed BLI’s testing,” says Matt Daniel, VP Product Development

at LD Products. “Now that we have these reports, we’re excited to refute the

misleading claims made by OEMs and remanufacturers with fact-based information

about how well our GOLD Line new-build cartridges perform in both reliability

and yield attainment,” he added.

According

to Christian Pepper, President of the LD Products Channel Partner Division, the

BLI results confirm what they already knew from their own internal lab testing

which followed an extensive product sourcing process in China. “We have

recently published a series of testimonials from leading dealers as to the results

they saw in their fleets, and now we have irrefutable data of how our

cartridges performed against OEM in a head to head test by the industry’s

leading 3rd party testing organization,” he stated.

“This

report further positions the LD Gold Line as a clear leader in the aftermarket

supplies industry and we are excited to share the results of BLI’s testing with

our customers.”

The two cartridges involved are the

9,000-page CF226X and the 40,000-page extended-yield toner cartridges (compared

with the 25,000-page original HP CF281X toner cartridge).

The BLI report included comments

such as, “LD Gold Line cartridges produced good overall quality. Solids from

the LD Gold Line toner were darker and richer than those produced by HP … All

LD Gold Line cartridges tested operated reliably, completing testing with no

malfunctions, and they surpassed their rated yields.”

Pepper

says the full results will be made available to dealers at the ITEX Expo in Las Vegas on April 24 and

25. In 2018, LD Products claims it achieved the industry’s lowest return rate

of 0.1%.

Details:http://www.rtmworld.com/2d/news/independent-tests-reveal-new-build-cartridges-compare-favorably-with-oem/

14.06.2019

HP DEFENDS ITS INK JET PATENTS

IN CHINA… AGAIN

Following a much-publicized case in

April 2016, HP is going back to the courts in China to once again defend its intellectual property (IP) rights against a cartridge

supplier based in Zhuhai, China. HP has used its Chinese

entity, China HP Co.,

Ltd. 中国惠普有限公司 (China HP) as the

plaintiff in the Shanghai IP Court (established in the last four years) against Zhuhai Sharing Color Printing

Consumables Co., Ltd. 珠海市韶运打印耗材有限公司 (Sharing Color).

China HP officially docketed two

complaints on March 20 and served Sharing Color on April 12, 2019. Two

complaints have been filed because there are two patents involved, being

ZL200680056896.9 and ZL200580011727.9 respectively. China HP has filed two

separate cases because each patent has to have its own case in China. HP’s patents

relate to “addressing and multiplexing circuitry on the inkjet printhead.”

China HP is accusing Sharing Color of infringing

the two patents with the distribution and sale of “clone”, or copycat, 803

integrated inkjet cartridges—HP’s current generation print cartridges with a

printhead. HP views this popularly used, latest hi-tech version of its print

cartridges as a “bread and butter,” mainline cartridge.

In RT Media’s view,

the allegedly infringing products have been, and continue to be, distributed

and sold primarily within the Chinese domestic market. Even though the

manufacturer of the cartridges has not been identified in the complaint, a

source close to HP has told RT Media they know who it is.

HP

is requesting RMB ¥ 1.5 million in each case for a total of ¥ RMB 3 million in

damages and also requesting an injunction against any further sales of what it

considers to be infringing products. The docket numbers are (2019) Hu 73 Zhi

Min Chu No. 174 and 175.

HP considers the ZL200580011727.9

patent to be particularly strong in China. This same HP patent was

involved in a complaint against Speed Infotech of Shanghai in 2015 in a highly

publicised case—being the very first case to be heard in the newly formed Shanghai IP Court. HP’s patents were validated.

But Hewlett-Packard Development Company, L.P. (惠普发展公司有限责任合伙企业) and Speed Infotech settled out of court.

At

the time, Speed Infotech was accused of distributing and selling infringing

integrated inkjet cartridges manufactured by MicroJet Technology Co. of Taiwan.

Microjet filed invalidity requests at the China Patent Office, and the Patent

Office ruled that the patents were valid. This ruling was then appealed

at the Beijing Intellectual

Property Court, which also ruled, in HP’s favour,

the patents were valid. It can be assumed HP believes it has a

particularly strong patent having withstood the most rigorous scrutiny in the

Chinese court system and found to be both valid and infringed.

Because of the good press back in

2015 and 2016, it would appear there have been no further cases of

infringement. Certainly, HP has not pursued any Chinese companies in China, until

now. Others had been found to be infringing within the Chinese domestic market

in the past, but all have either ceased that activity or gone out of business,

probably because of the publicity HP has generated with its success in China and

worldwide litigation.

Despite the many criticisms China has

received in the past over the protection of IP rights, HP’s recent experience

with the Chinese legal system would suggest otherwise. The establishment of

intellectual property courts in Beijing, Shanghai, and Guangzhouin 2015, to more efficiently adjudicate cases related to the infringement of

patents, copyrights, and other intellectual property, must be seen as a

priority for the Chinese government.

Details:http://www.rtmworld.com/2d/news/hp-defends-its-ink-jet-patents-in-china-again/

In English

In English

In Russian

In Russian