|

B4/C3

DELACAMP AG

Germany

Bargkoppelweg 64, Hamburg, 22145

DELACAMP, with its main office located in Hamburg, Germany is a leading supplier of components and consumables to the remanufacturing industry as well as consumables, components and spare parts for copier machines worldwide. In order to provide superior service to its customers, Delacamp holds a large selection and inventory of matched quality components at competitive prices for immediate delivery. DELACAMP is the exclusive distributor of MK Imaging, DC SELECT, CPT and Kaleidochrome branded products in EMEA. DELACAMP: Serving customers since 1879.

For more Information on DELACAMP visit their website at www.delacamp.com.

PRODUCTION: Consumables for the Recycling of cartridge: toner, drums, spare parts

Information from DELACAMP AG

19.03.2022

09.09.2021

Myth busting a moving target

Volker Kappius, CEO Delacamp AG

Single-Use cartridges, or better

single-use by design cartridges, need to be a thing of the past. Delacamp has

been actively supporting the genuine office imaging equipment cartridge

preparation for re-use, what we call remanufacturing, industry for many years

starting at a time when most other players have not been around or have been

active in other industries before embarking on the imaging reman industry.

OEM single-use plastic cartridges have

been the main target for the genuine reman industry as they come with the OEM

printers, replacement cartridges are heavily overpriced and reman companies can

fast learn how to remanufacture them as the components used are pretty much

standardized around the globe. With a used OEM cartridge (core) you know what

you get and with what you need to use and do to remanufacture it as quality

aftermarket components distributors like Delacamp will quickly offer full

solution of components, spare parts, OPC and toners needed for the

remanufacturing.

With the rise of the newly built

cartridges (NBC) this picture has changed. NBCs are also single-use be design

plastic cartridges. They do not come with the printer and they are very cheap

in price and often in quality. But depending on their market share in a given

market, they need to become a target for remanufacturing because they are the

only easy to get cores. The issue with the newly builds is that unlike with the

OEM core each Newly build is a moving target because the inner cartridge design

as well as the components used are not only different among the different

manufactures of newly builds for a given OEM cartridge type but can also vary

within one cartridge type of one manufacturer because of constant pressure to

keep low prices.

These moving targets, even if those

cartridges seem to be reman friendly because they have a fill hole for example,

are in fact a remanufactures nightmare because his standard “tool box” for the

cartridge is not fixed but needs to be adopted depending on the innards found

in each core.

In order for the newly built cartridges

to be a true myth buster, they need to have a stable quality not only in terms

of print quality but also in terms of the combination of parts used in any OEM

compatible cartridge. To make remanufacturing of these cartridges easier and

efficient, each change of components needs to be alerted to by a mark on the

plastic (e.g. mark I, mark II, etc.). Even better of course, would be the use

of components in a newly build that can survive more than one cycle and a

special web site of each manufacturer of newly built cartridges available to

cartridge remanufactures with tips on how to best remanufacture each cartridge

and their costs driven evolutions (e.g. mark I, mark II, etc.).

Furthermore, newly built cartridge manufactures should start to proactively use

non contaminated toners, components and plastic parts and not reluctantly react

if industry organizations find out that they are in breach of regulations, laws

and accepted health standards.

Without the above, the me-too green mask

of newly builds is just a lip service and re-fill shops will keep on refilling

the NBCs only because of a lack of OEM cores and to make the cheapest possible

cartridge for producing an output for which print quality is not important.

The newly built cartridge players in

China have become big corporations and are in most cases even listed companies

on Chinese stock exchanges. They have the size, the money and probably also the

know how to design and manufacture a much more sustainable product. But their reluctance

to do so only stresses that they are in for the quick money and not for the

environment and the health of their cartridge users. Their fire and forget

mentality still prevails.

This is the main difference between the

genuine reman and the newly built cartridge industry: Care (reman) vs. greed

(NBC).

18.02.2021

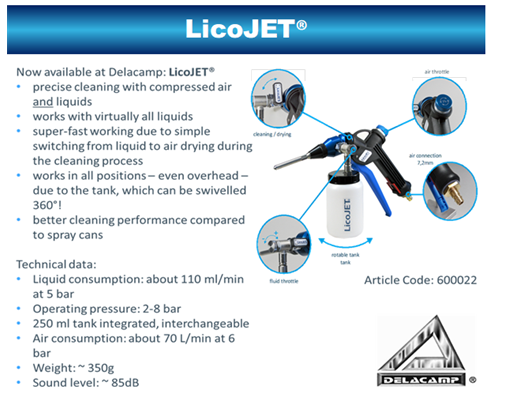

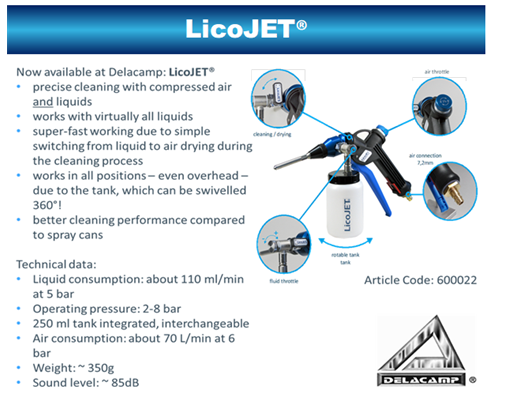

DELACAMP AG announced a new product -

LicoJet® cleaning tool

The latest product added

to Delacamp’s product range is a cleaning tool named LicoJET®.

It is a great tool for

cleaning IJ heads and used components. It allows precise cleaning with

compressed air and liquids. Super-fast working due to simple switching from

liquid to air-drying during the cleaning process is an excellent and timesaving

feature.

For more information on the above-mentioned or more of Delacamp’s

product range, visit www.delacamp.com or

contact us info@delacamp.com.

15.12.2020

18.11.2020

Quality

cannot be proclaimed but needs to be proven and earned!

Volker Kappius, CEO, Delacamp AG,

answers the questions of Information

Agency «BUSINESS-INFORM»

- How in your opinion has the market of printing supplies changed in

2020? How has the COVID-19 pandemic changed the Global market and the work

of your organization?

The worldwide pandemic has been a big

disruptor. Lock- and shut downs are having a big negative influence on the

economic performance and having to work from home is having a big influence on

the availability of empties because household electronic waste can hardly be

included in collection systems. In addition home office users tend to use very

small footprint printers like small Ink Jet and laser printers. And since color

printing is very popular, the printers at home are mostly small foot printer

Ink Jet color printers for which supplies are being bought mostly online for convenience

reasons.

In order to minimize a possible impact of a

Covid-19 infection at Delacamp, we have some staff members working from home on

certain days but since pretty much everybody is having his own office and we

have implemented strict hygiene and social distancing measures at Delacamp the

number of people working from home is limited.

I have to admit that before I never ever had

more meetings with people outside of Delacamp per month. Online conferencing

has become a standard part of an office day in the pandemic and is definitely

here to stay even after the current pandemic is over.

- How interesting are the quality (and correspondingly more

expensive) printing supplies for the modern customer in the pandemic

conditions?

Although buying online is very convenient, having to return products

that do not work as expected and having to buy a replacement is troublesome. I

hate to admit it, but printing and printing supplies are low involvement items.

Users want to order and print. They do not want to worry about the supply until

the supply runs empty. This insert-and-forget mentality and demand can only be

satisfied by high quality and OEM supplies. But because users do not only want

to insert-and-forget but want to save money as well, high quality aftermarket

supplies are the product of choice during the pandemic. On top of that, the pandemic

has revealed that global supply chains are prone to disruptions. The local and

environmentally better alternative is in most cases the better choice.

- On what (in terms of Global market) do the sellers base the

evaluation of quality of consumables sold: their own experience, the

colleagues’ opinion, testing results, advertising? Can all consumables

sold on the Global market as “quality” ones be really attributed to being

quality materials?

“Quality” is not a registered trademark and everybody can use it.

Quality cannot be proclaimed but needs to be proven and earned. The perceived

quality of consumables is dependent on many factors. The factors include:

· Quality

(print output and emissions) of the components used in the consumable.

· The

way how these components are being assembled to manufacture the consumable.

· In-house

testing routines and methods.

· Paper

used for testing.

· Level

of regulatory compliance, etc.

Only testing in-house or by a trusted laboratory will give you security.

- Is it a must for distributors of quality supplies to have their

quality control laboratories? Or is it enough to have statements by

manufacturers confirmed with their certificates?

Testing by distributors of quality supplies only really makes sense if

the distributor, like Delacamp, offers the full range of products needed to remanufacture

a printer cartridge. If a supplier of toner only is doing testing, it will very

probably only be with an OEM cartridge where the toner is being dumped and

replaced by their own toner. This is not a realistic testing set up and

scenario. The same is true for all manufactures or distributors who only offer PCRs,

OPCs, etc. The only exception is chips. They can pretty much be tested with any

cartridge.

And

the impact of paper quality on testing must not be underestimated. Testing with

a soft white hue 80gr. smooth surface paper with little amount of chalk as a

filler will produce very different results than a 75gr. rougher surface and

high chalk content cheap paper.

- Who must explain to the customers the value of quality consumables:

manufacturers, distributors, resellers? Is it worth the money and energy at all?

The quality benchmark is the OEM. But the OEM is also the most expensive

and together with Newly Built cartridges from the Far East the least

environmental sound alternative. If we are to promote quality and educate the

end-user on quality it needs to be a team effort. The End-User has to

understand that the cartridge is made by a quality focused manufacturer using

quality oriented manufacturing and testing methods with the highest quality

components available with great service quality supplied by the distributor.

If one decides to save money and energy on quality he chooses to enter

the price-only ball game only. This is a game where you can only lose because

someone will always be cheaper. The shark tank is open to be joined by anybody

who wishes to throw quality over board.

- Should the customers trust the testing done by the supplier of

customers, since this type of testing almost always confirms “the high

quality” of the supplied product?

If the supplier has built track record of reliably supplying quality

products, than this supplier can be trusted and regular random checks can be

enough. But if the supplier has not be able to build a positive track record

and/or is selling different products/build specs under the same product code

you cannot afford not to test. It is your reputation that is at stake. The

reputation you have been building over many years.

- What in your opinion must be included in the term “quality of

printing supplies”? The quality of prints? Or the wider set of characteristics: the convenience for

remanufacturing, environmental friendliness, informational safety, etc?

For printing supplies there is an easy answer for me:

· Repeatable

quality of the print (ID, fixation, yield, level of background, color gamut,

gloss level, etc.).

· Emissions

(none or low) of printing consumable (Ink or Toner).

· Regulatory

compliance (in the target country of the printing supply).

· Environmental

impact of manufacturing and transportation.

· Complaint

management.

· EOL

(End-of-Life) solution.

22.10.2020

Mitsubishi Chemical

Corporation and Delacamp Announce the Prolongation of the Exclusive Distributorship for Europe, CIS, the Middle East and Africa

Delacamp AG, the largest independent

supplier of quality components and consumables to the genuine printer cartridge

remanufacturing industry has been chosen again by Mitsubishi Chemical

Corporation as their sole and exclusive distributor of OPCs and Chemical Toners

for Europe, CIS, Middle East and Africa.

“We are very delighted to continue this

long-term successful partnership and are proud to mark the 15th year

of successful cooperation with Mitsubishi in 2021.

The year 2020 is a difficult year. It

presents us all with new challenges. The global spread of the SARS-CoV-2 virus

and the measures to slow the virus spread affect both social life and the

global economy. We are all affected in some way and most of us have had

difficult months this year. I had been promoted to Sales Manager at the

beginning of this year and honestly speaking I expected my first year in the

new role to be quite a bit different. However, it makes me very proud working

with such a good team, customers and business-partners that let us get through

this challenging situation and year. I would like to use this opportunity to

thank our long-term business partners and absolutely loyal customers – thank

you very much!” says Susanne Dannehl, Sales Manager of Delacamp.

02.05.2020

Throw

Away the Concept of Throw Away

Volker

Kappius, CEO Delacamp

Successful business models and

products get copied. The degree of competition between original and me-too is

really only limited by how successful the business model or the products in

their respective markets are and how high the entrance barrier to move into

that particular market is. In most cases the perceived entrance barrier is much

lower than the actual one, because some entrants are willing to take the risk

to not to comply with all necessary requirements. In most

cases the more mature a new entrant into a market is and the more money he has

made in that market, the more he is likely to comply with more and more

requirements because he can now afford it and he needs the true height of the

entrance barrier as a shield against new entrants. No rocket science here.

The same principle only seemingly

applies to the imaging cartridge industry. At a first look one might argue,

that the OEM razor and blade business model was successful enough to be worth

copying, the entrance barrier to moving to machines was too high, the entrance

barrier to moving to selling single use cartridges seemed low. But this is not

how the cartridge imaging aftermarket industry started. Actual it started way

more disruptive. In the late 80s the pioneers of the cartridge remanufacturing

industry looked at a cartridge and the profitable business model but challenged

that a cartridge is a single use throw away product. Hence they started

collecting the waste empty cartridges and used them as a core to remanufacture

them in order to give them a second life and to have a product to compete

against the OEM single use cartridges.

This remanufacturing business model

was then seen by others companies as being lucrative enough to be worth

copying. So they did. But eventually it became too time-consuming and too

troublesome and expensive to collect empty cores in different countries, ship

them to their factories, remanufacture them and then send them back for sales

in the same countries where the cores have originally been collected. In addition

cheap raw materials and cheap plastics which had been partly derived from waste

plastic collected over years were readily available and were easy to be used

because black plastic can hide a lot. So instead of re-using a former

single-use plastic product, these companies made their own single-use plastic

products. Only they made it way cheaper than OEM products and even cheaper than

remanufactured products because the perceived entrance barriers into moving to

new single use plastic cartridges were low. We are now seeing that the main

companies who copied the remanufacturing business model but then moved into

single-use cartridges are trying to be more and more compliant but have not

fully overcome the true entrance barrier laid out by all necessary requirements

to be fully compliant in each target market.

Legal entrance barriers in to the

cartridge market are actually very high in most developed countries like

Russia, the EU countries and the US. Legal entrance barriers include among

others:

· IP

(civil law)

· Local

laws and regulations on health and safety, waste management, the environment,

importation, VAT and other taxes, etc. (criminal law)

Every time a mature player becomes more

compliant he usually flanks this by marketing activities as we can currently

see on IP compliance. IP compliance has become an important target as IP is

civil law and the patent holder can easily sue companies not in compliance. We

have seen this in the past years quite often.

Unfortunately, we are seeing way

less activities of government bodies in policing and sanctioning noncompliance

on laws and regulations. Russia seems to be moving forward in doing so. But the

lack of policing does not mean that companies can take a free ride. This is

especially true when it comes to health and safety issues as we have seen with

DecaBDE and are now seeing with high levels of CMR (carcinogenic, mutagenic, or

toxic for reproduction) substances, VOCs (volatile organic compounds) and heavy

metals found in newly build cartridges bought online and from dealers in the

EU.

Buying cheap too often comes with

buying substandard and even worse - with buying in possible health issues.

But in today’s world there are more

things of high interest than only the mandatory compliance to IP and law and

regulations. Because of limitations of natural resources and limitations on

what our planet can absorb and take compliance to issues around sustainability is

becoming more and more prominent. Fridays For Future is only one well known

example. Eventually only so called green or greener business models can

survive.

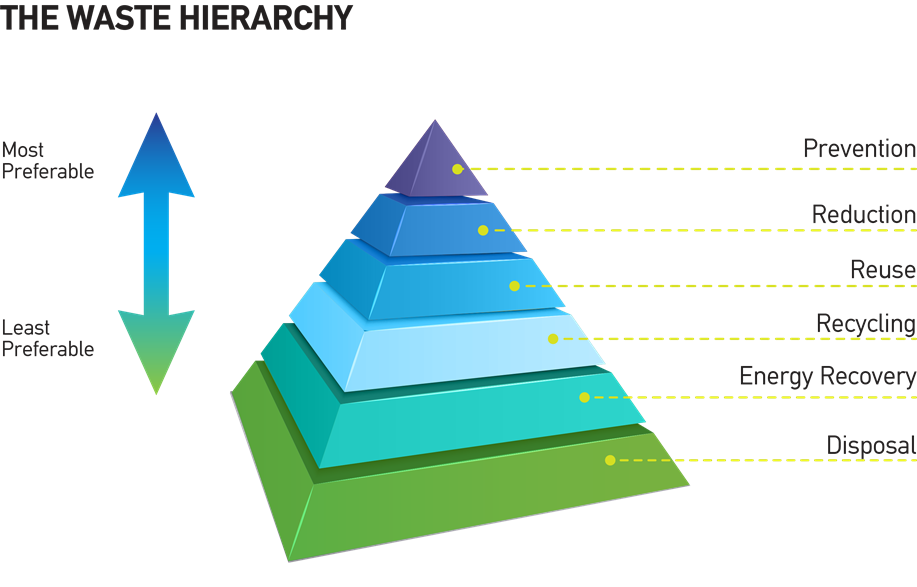

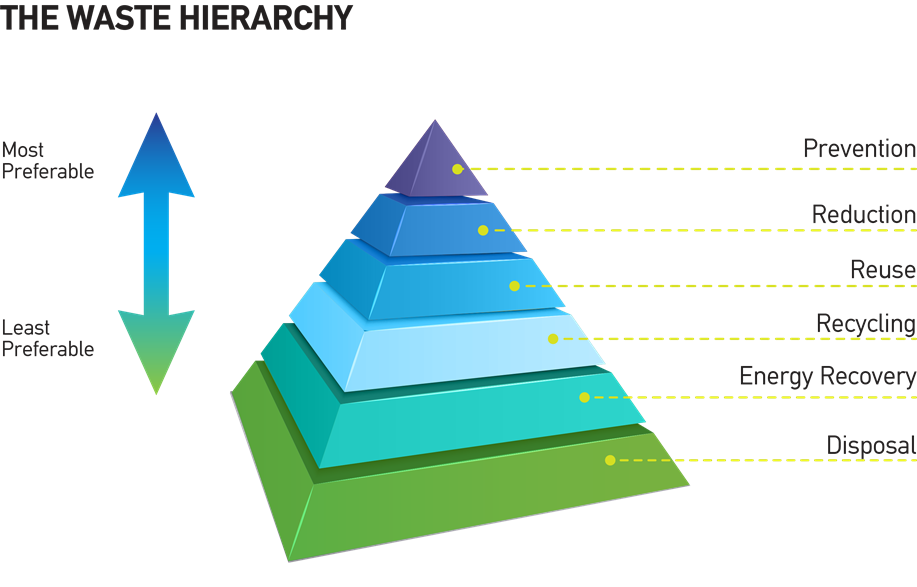

The remanufacturing industry is a

text book example of a circular economy based business model. A product that is

supposedly waste is being collected, prepared for re-use through

remanufacturing and eventually resold and re-sued by and end user. This circle

goes on and on until, in the case of the cartridge, the cartridge has reached

its true and of life and is eventually being handed over to the raw material

recycling. This is all in line with the waste hierarchy (see graph below).

In addition to contributing to global

sustainability, the remanufacturing industry is generating local jobs because

of the collection, the transportation, sorting, remanufacturing, sales and

distribution processes involved. The quality of the remanufactured cartridges

can be controlled by the quality of the used empty core as well as the quality

of the toner, OPC and parts and the standards like LEM or STMC used in the

remanufacturing process.

Newly build cartridges already fail at the top

levels of the waste hierarchy. Using all new raw materials for a mere me-too

throw away product is far from prevention and reduction.

In today’s society all throw away single use

products for which there is no alternative, must be a thing of the past. And

for cartridges there has been an alternative for a single use product around

for over thirty years known as remanufactured cartridge.

Details: BUSINESS-INFORM Review (issue #27, 2020)

|

|

|

In English

In English

In Russian

In Russian